High Precision Micro-Components Fabricated by Additive Manufacturing

source:laserfair.com

release:Johnny

keywords: Nanoscribe 3D printing

Time:2017-11-21

At formnext, the leading trade fair for additive manufacturing in Frankfurt a.M. (Germany) Nanoscribe brought 3D micro printing and conventional serial production technologies together.

Complex designs, faster iteration processes, and shorter product life cycles require manufacturers of micro-optical, microelectronic, and microfluidic components to be more flexible. A particular challenge is the production of free-form structures with resolutions below 10 μm, which is difficult to accomplish with conventional production methods.

With the Photonic Professional GT, Nanoscribe provides the world’s highest resolution 3D printer for the fabrication of highly complex nano- and micro-structured plastic components with structure sizes up to a few millimeters. based on the technology of direct laser writing polymer masters can be directly and rapidly fabricated from CAD models. Subsequently the 3D printed polymer master can be used for making molds, e.g., for injection molding or hot embossing. This approach enables cost-efficient reproduction of the printed parts in large quantities and with a high degree of shape fidelity.

Polymer Master for Micro-Tooling:

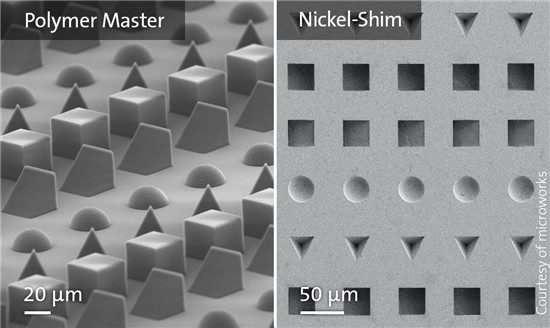

Polymer masters can serve to transfer, for example, 3D printed micro-optical shapes into serial manufacturing. Micro-optical elements like microlenses, prisms or retroreflectors can be additively produced with a high degree of dimensional accuracy what opens a multitude of new applications, e.g., in medical engineering or the smartphone industry. In this manner 3D printed micro-optics can have vertical slopes, sharp edges, asymmetric geometries, and arrays of different elements and serve as a polymer master. The polymer master can then be molded into a nickel-shim by means of electroforming. In this process, the 3D printed polymer structure is sputtered with a thin metal layer. A nickel-shim is then electrodeposited onto this. The replica mold produced in this way can be integrated into the process chain of various injection molding procedures and thus provides the basis for further series production.

Printing Process:

Nanoscribe systems operate on the basis of two-photon polymerization (2PP), in which a laser beam exposes a photosensitive material in order to cure it in the focal point. Using a layer-by-layer process, virtually any 3D polymer structure can be printed. This method allows to achieve submicron features sizes down to 200 nanometers and highest precision on a writing field of a few millimeters. When common additive manufacturing technologies like stereolithography reach their limits, these 3D printers reveal their full potential and enable the fabrication of components that were previously unfeasible by additive manufacturing.

The software supports the printing process with a simple workflow and a user-friendly interface, from the STL data import and the 3D visualization of the writing process to the easy selection of recipes. These features allow to optimize the process and the properties of the printed object, such as printing time, surface finish and shape accuracy as known from other conventional 3D printing standards.

In order to maximize the performance of its 3D printers, Nanoscribe also supplies a product line-up of photoresists that are tailored to Photonic Professional GT systems. Each of these easy-to-use negative-tone photoresists targets different quality criteria such as resolution, surface smoothness, or throughput. Furthermore, a variety of other UV-sensitive materials are also suitable for the printing process. Samples can be produced from cell binding/repelling, hydrophobic and hydrophilic polymers with different mechanical characteristics as well as hydrogels. The compatibility of this highest-resolution additive manufacturing technology enables the direct fabrication onto a broad range of different substrate types, e.g., glass substrates or silicon chips.

From Micro to Meso:

Additional to the fabrication of micro-components and micro-structures, this technology also allows the production of micro-parts with dimensions up to the millimeter range like miniaturized gears, clamps, screws or spirals. Especially the watch and MEMS industry as well as fields in medical engineering can benefit from these innovative 3D printing solutions to reduce the time of their own product development processes and iteration cycles.

NEWS

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

INTERVIEW

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>