Ultrafast laser-inscribed fiber Bragg gratings for sensing applications

source:SPIE

Time:2016-06-14

UV laser-induced fiber Bragg grating (FBG) sensors are small in size, passive in nature, have immunity to electromagnetic interference, and are capable of directly measuring physical parameters such as temperature and strain. These features have inspired researchers to develop FBGs beyond the laboratory for mainstream sensing technology applications. Recently, high-temperature stable gratings made with femtosecond pulse-duration IR laser processing (fs-IR) have shown promise for use in extreme high-temperature, high-pressure environments, or in ionizing radiation, where UV laser-induced FBGs fail. Such gratings are ideally suited for energy production applications where there is a requirement for advanced instrumentation and controls that are operable in harsh environments.1

The FBG is a band-rejection optical filter within an optical fiber. It passes all wavelengths of light that are not in resonance with it, and reflects those that satisfy the Bragg condition of the high-power laser-induced core index modulation Δn, namely:

In this equation, λB is the FBG Bragg resonance or Bragg wavelength, ne# is the effective refractive index seen by the guided mode of light propagating down the fiber, and ΛG is the period of the Δn that makes up the grating (see Figure 1). FBGs are effective sensing elements, possessing all the advantages of fiber-optic-based sensing approaches over more established electrical sensor technology.2 The sensing function originates from the sensitivity of both the ΛG and ne# of the optical fiber to the immediately surrounding environment. As the FBG-reflected light is dependent upon ΛGand ne#, externally applied mechanical or thermal perturbations affect the FBG response directly, through the expansion or compression changes of ΛGand through the strain- and thermo-optic effects (i.e., the strain/temperature-induced change in the glass refractive index).

Commercial FBG interrogators that monitor spectral shifts in the λB have resolutions in the telecom band on the order of 1 picometer. Direct monitoring of shifts in λB results in minimum detectable strains of ∼1με/ # Hz rms at constant temperature and minimum temperature variations of 0.1°C in the absence of strain.2 Such FBG sensors have been used in civil structures, aircraft, naval ships, and oil pipelines as ‘ smart skin’ sensor webs to measure the in situ temperature and stress of these structures below 200°C. At more extreme temperatures (>450°C), however, standard UV-induced FBGs are unstable and erase.

FBGs inscribed with fs-IR lasers can be thermally stable up to the fiber glass transition temperature. They can be induced in any optical fiber3 by exploiting non-linear multiphoton photosensitivity mechanisms (which are significantly different from the UV-induced color-center formation photosensitivity mechanisms).4 Thermally stable FBGs can be used for sensing in harsh environments within power plants, turbines, combustion systems, and in the aerospace sector. Such FBGs are fabricated using either a phase mask3 or a ‘ point-by-point’ approach.5 The phase mask is typically a silica transmission diffraction grating that is precision-etched so that the laser light used to write the FBG creates an interference pattern. This pattern generates the index modulation (Δn) in the fiber core. The ‘ point-by-point’ approach involves a microscope objective and a precision translation stage, and then creation of the Δn using single high-intensity pulses for a femtosecond laser. This creates individual grating planes through a step-and-repeat approach.

In the oil and gas sector, thermal techniques for unconventional oil recovery create harsh downhole environments. When subjected to these conditions, fiber optic sensors are hampered by optical losses that result from ingress of high-temperature hydrogen gas. This is especially true for standard germanium-doped telecom fibers. Using pure silica core fibers that do not suffer from hydrogen-induced attenuation can mitigate these effects.6However, FBG-based distributed sensing arrays are extremely difficult to produce in pure silica core fiber using conventional UV-laser-based inscription. Using the fs-IR approach, it is possible to write high-Δn FBGs easily in pure silica optical fibers, which are then resistant to hydrogen-induced loss.7 The use of such fibers is essential for improving sensor array performance to monitor (for example) steam-assisted gravity drainage in the oil and gas industry.

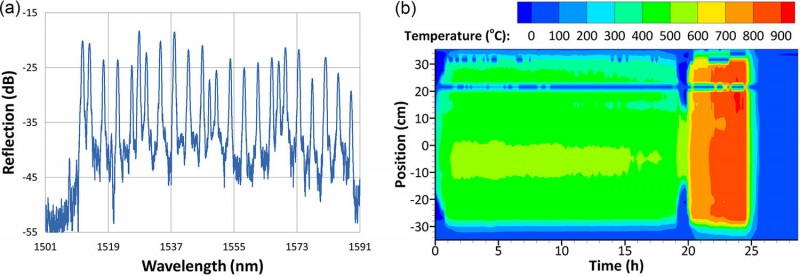

We recently deployed the fs-IR technique at a site in Canada where a research organization is exploring the use of oxy-pressurized fluidized bed combustion for power generation.8 For optimal efficiency, this combustion process requires accurate measurements of temperature gradients within the combustor, and these measurements are difficult to realize using standard electronic thermocouple technology. At the research site, we deployed seven arrays containing 132 fs-IR laser-written type II FBG temperature sensors to the internal thermal gradients of the fluidized bed pilot combustor. Figure 2shows the reflection spectrum of one of the fiber arrays, as well as temperature mapping within the fluidized bed combustor as a function of position and time during part of one thermal cycle of the combustor. The sensor arrays performed well over five months through multiple thermal cycles of up to 1025°C. The advantages of this fiber optic deployment were clearly demonstrated with respect to cable management, ease of installation, high density of sensing points,' and more rapid response to thermal changes' compared with an electronic thermocouple approach.

In summary, fiber Bragg gratings made with femtosecond pulse duration lasers in silica fiber have thermal stabilities that make them effective sensors in high-temperature environments. We successfully deployed a quasi-distributed FBG temperature sensor array made with an IR femtosecond laser within an oxy-pressurized fluidized bed combustor. We are now working to improve sensor performance through optical fiber design and sensor packaging. This includes investigations into crystalline-based fibers such as sapphire.

Stephen Mihailov is leader of the Fibre Photonics Group. He is an experimentalist with over 25 years of experience in scientific research involving material processing with high-powered laser systems. He has more than 200 publications and 19 issued US patents.

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>