High-Power Pico Laser SiC Dicing: TIMESHIFT Pulse Advantages

source:mkS | spectra-Physics

keywords:

Time:2025-11-20

Source:mkS | spectra-Physics 1st Nov 2025

Silicon carbide (SiC), a semiconductor substrate material, has garnered significant interest from electric vehicle (EV) and power electronics manufacturers due to its numerous advantages over traditional silicon-based electronic devices in these applications. However, SiC's material properties differ substantially from those of silicon, meaning many existing IC manufacturing processes are either partially incompatible with SiC or entirely unsuitable.

Die dicing is a typical example. As the primary method for silicon die separation, mechanical sawing cannot be fully applied to SiC. One key challenge is that SiC is among the hardest known materials, with a hardness nearly equivalent to diamond. Consequently, sawing SiC generates chips that rapidly wear expensive diamond blades, results in relatively slow cutting speeds, and produces heat that can alter material properties.

In this application focus, we will review the latest laser technologies developed to overcome these challenges and present solutions for processing SiC materials.

Non-contact laser dicing offers an highly attractive alternative for SiC processing. Ideal laser processing minimizes or eliminates edge chipping and reduces material mechanical modifications (cracks, stresses, or other defects) to a minimum. Additionally, it can maximize the reduction of kerf width to maintain small "keep-out zone" dimensions (the empty space between adjacent circuits), thereby significantly increasing the number of dies per wafer. Ultrashort pulse (USP) lasers, particularly those operating at ultraviolet (UV) wavelengths, are well-known for exhibiting these advantages in high-precision cutting and ablation of hard, transparent, or brittle materials. At the same time, achieving high throughput by combining short pulse widths and short wavelengths remains a significant challenge.

Considering these factors, we conducted experiments to optimize SiC dicing processes using the MKS Spectra-Physics? IceFyre? UV picosecond laser. We specifically investigated the impact of the TimeShiftTM programmable pulse function on pulse train customization.

The test samples consisted of 340μm-thick 4H-SiC material. Leveraging the laser's programmable pulse train capability, we produced various dices using pulse configurations ranging from single pulses to 12-pulse trains.

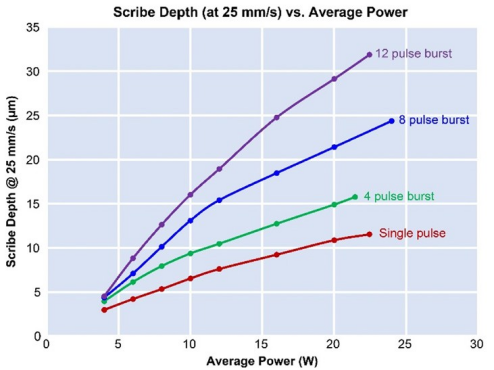

Figure 1. Dicing depth as a function of power for a single pulse and various pulse train configurations (4-12 sub-pulses per pulse train) at a net speed of 25 mm/s. Clearly, the pulse train configuration has increased the ablation rate.

The overall results are shown in Figure 1, which depicts the dicing depth for various pulse train configurations as a function of average laser power. In each test, a total of eighty high-speed dicing passes were performed at the same location on the material. Leveraging the TimeShift function of the IceFyre laser, the position of each pulse train on the workpiece surface (e.g., total pulse overlap) can be precisely controlled. In this case, the effective spatial overlap rate of the pulses was approximately 84%, achieved by a staggered configuration of multiple pulses with fewer overlaps.

This data clearly indicates that the use of pulse trains significantly increases the ablation rate, consistent with results from pulse train processing in other materials and with other pulse widths.

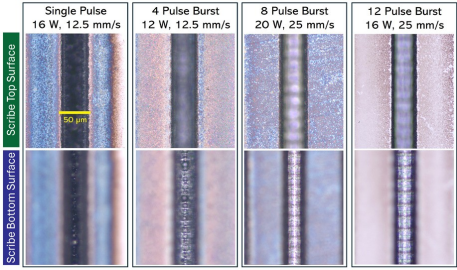

Figure 2. Microscopic images showing the top and bottom of 25 μm deep grooves. These images demonstrate that as the number of pulses in the pulse train increases, the dicing quality steadily improves.

For the qualitative evaluation of dicing quality, a series of photographs were taken. These images are shown in Figure 2. Specifically, they are microscopic views of a series of 25 μm deep grooves fabricated using 1, 4, 8, and 12 sub-pulses per pulse train. In each case, the average laser power and net speed were adjusted to achieve optimal quality at the target depth of 25 μm.

In the upper row of photographs, the microscope is focused on the top surface of the wafer, while in the lower row, the focus is on the bottom surface of the diced grooves. As the number of sub-pulses in the pulse train increases, the overall feature quality improves significantly.

Notably, with the increase in the number of pulses, the discoloration around the diced area gradually diminishes and eventually disappears entirely. Such discoloration typically indicates some form of change in the surface or bulk material, possibly due to surface oxidation caused by material overheating.

The photographs in Figure 3 show only the bottom surfaces of a series of diced grooves, this time at a higher magnification. In this set of tests, each dice was performed under the same laser operating conditions: an average power of 16 W and a net scanning speed of 25 mm/s. The dicing depth for each condition is indicated in the figures.

Figure 3. As can be seen from these images, excellent processed surface quality can be achieved using picosecond ultraviolet (UV) laser processing. The advantages of pulse trains with a high number of pulses are clearly evident here.

This higher-resolution view makes the improvement in surface smoothness more pronounced as the number of pulses increases. Notably, with constant average power and overall processing speed, customizing the pulse output using the TimeShift function can triple the dicing depth.

This test demonstrates that ultraviolet (UV) picosecond lasers are capable of producing ultra-high-quality dicing on SiC chips. Furthermore, the test clearly validates the advantages of TimeShift pulse train programming. In particular, it shows that a higher number of pulses results in better dicing quality and a higher feed rate. This outcome is encouraging, as it indicates that SiC dicing using the IceFyre picosecond laser with TimeShift functionality can achieve both the throughput required for production and the desired quality, thereby enabling high cost-effectiveness.

Product: IceFyre Industrial Picosecond Laser

The IceFyre UV50 is an outstanding ultraviolet (UV) picosecond laser on the market, delivering >50W of UV output power at 1.25 MHz (>40), with a pulse energy of 100μJ in pulse train mode and a pulse width of 10 ps. The IceFyre UV50 sets a new standard for power and repetition rate, ranging from single-shot to 10 MHz.

The IceFyre UV30 provides a typical UV output power of >30W and pulse energy of >60μJ (higher pulse energy in pulse train mode), boasting excellent performance from single-shot to 3 MHz.

The IceFyre IR50 delivers >50W of infrared (IR) output power at 400 kHz in single-pulse mode, with superior performance spanning from single-shot to 10 MHz. The unique design of IceFyre lasers leverages the flexibility of fiber lasers and Spectra-Physics' exclusive power amplifier capabilities, enabling TimeShift ps programmable pulse mode technology with industry-leading versatility.

Each laser comes with a set of standard waveforms; the optional TimeShift ps GUI allows for the creation of custom waveforms. The laser is engineered to feature industry-leading low timing jitter Pulse-on-Demand (POD) and Position Synchronized Output (PSO) triggering functions, facilitating high-quality processing at high scanning speeds (e.g., with polygon scanners).

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>