The Application of Laser Welding Technology in the Manufacturing of Power Batteries

source:High Energy Beam Processing Te

keywords:

Time:2025-11-04

Source: High Energy Beam Processing Technology and Application 21st Oct 2025

1. Introduction

Amid the global trend of the automotive industry transitioning to electrification, power batteries—the core energy source for new energy vehicles—determine the market competitiveness of electric vehicles through their performance, safety, and cost. The manufacturing of power batteries is a complex multi-disciplinary process involving materials science, electrochemistry, and precision machinery. Among its key steps, high-quality connection technology serves as a crucial link throughout the entire process.

Traditional connection processes such as resistance welding and ultrasonic welding gradually show limitations, including large thermal impact, poor consistency, and narrow process parameter windows, when addressing the large-scale, automated production of power batteries and handling high thermal conductivity materials like copper and aluminum.

Laser welding technology, with its distinct advantages such as high energy density, controllable heat input, non-contact operation, and easy automation, meets the strict requirements for precision, efficiency, and reliability in power battery manufacturing. It has thus become a core process spanning the entire workflow from cell manufacturing to battery pack assembly.

This article aims to elaborate on the specific applications of laser welding technology in different manufacturing stages of power batteries and summarize its significant role in advancing the development of the power battery industry.

02 Application in Cell Manufacturing

The cell is the basic unit of a power battery, and its manufacturing precision and sealing performance are the fundamental guarantees for battery safety and performance. Laser welding is mainly used for the precision connection and final sealing of cells.

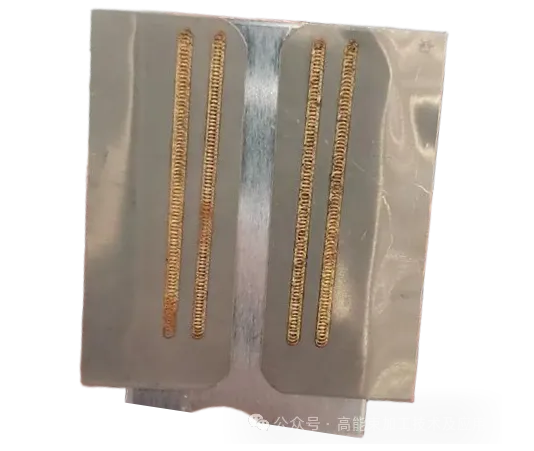

First, in terms of the internal electrical connection of cells, laser welding is applied to tab welding. After the winding or lamination process is completed, it is necessary to firmly weld the tabs of the positive (aluminum foil) and negative (copper foil) current collectors—which consist of dozens or even hundreds of layers—together, and form a reliable electrical path with external poles or adapter plates, as shown in Figure 1.

Laser welding can instantly fuse these thin sheet materials with an extremely short pulse time, forming welds with low resistance and high strength. Its advantage lies in the extremely small heat-affected zone, which effectively prevents welding heat from damaging the adjacent separators and active materials, thereby protecting the electrochemical performance of the cell.

Figure 1. Laser Welding of Lithium Battery Cells

Secondly, in the final packaging stage of cells, laser welding is one of the effective methods to achieve hermetic sealing. Meanwhile, laser welding is used to connect the top cover to the case in prismatic aluminum-cased and cylindrical steel-cased batteries. Through precise control of laser power, speed, and focal position, a continuous, smooth, and dense weld seam can be formed on the case, effectively preventing electrolyte leakage and infiltration of external moisture, and ensuring the stability of the chemical environment throughout the cell's lifecycle.

For pouch batteries, laser welding is applied in top sealing and side sealing processes to weld the lead-out tabs to the adapter tabs (typically nickel-plated copper or aluminum) that serve connection and protection functions. Its non-contact nature ensures packaging efficiency and zero damage to the aluminum-plastic film packaging materials, as shown in Figure 2.

Figure 2. Laser welding samples of tab of pouch cell.

3. Application in Battery Module and Battery Pack Assembly

Integrating individual cells into modules and battery packs requires a large number of electrical connections and structural fixations, making this the stage with the most concentrated application of laser welding and the greatest technical challenges.

In terms of electrical connections, the core application is series and parallel welding between cells. By connecting busbars (usually aluminum or copper bars) to the poles of the cells, the entire circuit system of the battery pack is constructed.

Figure 3. Laser welding of lithium battery busbars.

The challenges in this stage lie in:

1) Material property challenges: copper and aluminum have high reflectivity to commonly used infrared lasers and fast thermal conductivity, making welding difficult;

2) 2) Joining of dissimilar materials: for example, the connection between copper busbars and aluminum poles easily forms brittle intermetallic compounds (IMCs), which affects the long-term reliability of the joint.

To address these challenges, the industry has developed advanced processes such as oscillating laser welding, hybrid welding (e.g., laser-arc welding), and lasers with new wavelengths like green/blue light. These technologies effectively suppress defects such as spatter and porosity, control the thickness of the IMC layer, and thus achieve reliable electrical connections by expanding the molten pool, enhancing stirring, and improving energy absorption.

In terms of structural connection, laser welding also plays a vital role. For instance, structural components such as module side plates and end plates used to fix cells, as well as the connection between battery pack enclosures and covers, can all be joined via laser welding. Compared with traditional screw or rivet connections, laser welding achieves a higher degree of integration and structural strength, helping to enhance the battery pack’s resistance to vibration and impact.

Furthermore, tiny welds in the collection circuits of voltage and temperature sensors within the battery management system are increasingly using laser welding, ensuring the long-term stability and reliability of signal collection.

4. Conclusion

Laser welding technology, with its high precision, speed, and reliability, has been integrated into every process of power battery manufacturing. From the microscopic welding of cell tabs to the macroscopic structural connection of battery packs, and from the hermetic sealing that ensures cell safety to the low-resistance electrical connections that determine battery performance, laser welding plays an irreplaceable core role.

It not only effectively solves the processing challenges of difficult-to-weld materials such as copper and aluminum, meeting the requirements for efficiency and consistency in large-scale automated production, but also maximizes the protection of the battery’s electrochemical performance through precise control of welding heat.

The maturity and development of laser welding technology have become a key technological driver for improving the energy density, reducing manufacturing costs, and enhancing the safety performance of power batteries, providing a solid manufacturing foundation for the rapid development of the global new energy vehicle industry.

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>