Analysis: Opt Fibers in Laser Tin Soldering – Usage Specs, Loss Ctrl, Life Mgmt

source:

keywords:

Time:2025-09-17

Source: Dayan Intelligent Manufacturing 29th Aug 2025

In laser tin soldering systems, optical fibers serve as the core medium for laser transmission, and their performance stability directly affects the quality of soldering and the lifespan of the equipment. Through over two decades of application of laser tin soldering technology, Dayan Intelligent Manufacturing has found that more than 60% of equipment failures are related to improper use of optical fibers, with end face contamination, excessive bending, and power overload being the main causes. This article, based on practical experience in the field of precision electronic manufacturing, systematically elaborates on the usage norms and maintenance points of optical fibers in laser tin soldering, and introduces the technical design of Dayan Intelligent Manufacturing's equipment for optical fiber protection, providing a standardized operation reference for the industry.

I. Understanding the Characteristics of Optical Fiber: Recognizing Fragility is the Prerequisite for Standardized Use

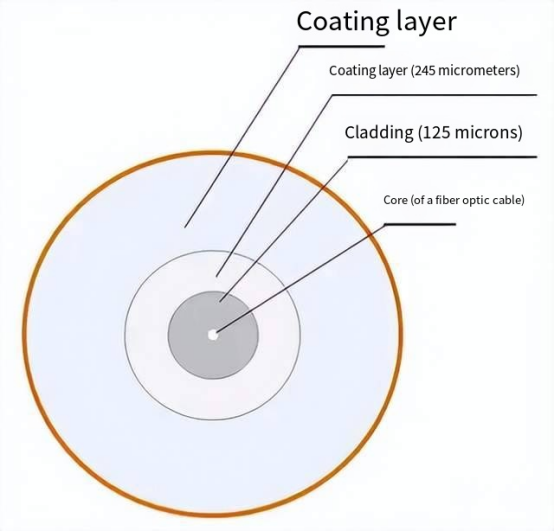

The optical fiber used in laser soldering is made of fused silica (SiO?), and its physical properties determine that special protective measures must be adopted. Although this material has high light transmittance (transmittance of 1064nm laser > 99%) and high-temperature resistance (softening point > 1700℃), its mechanical shock resistance is extremely weak - the core diameter of the optical fiber is only 50-600μm (equivalent to the thickness of a human hair), and the surface coating layer (acrylic or polyimide) is the only mechanical protection. once damaged, it will cause a sharp increase in laser transmission loss.

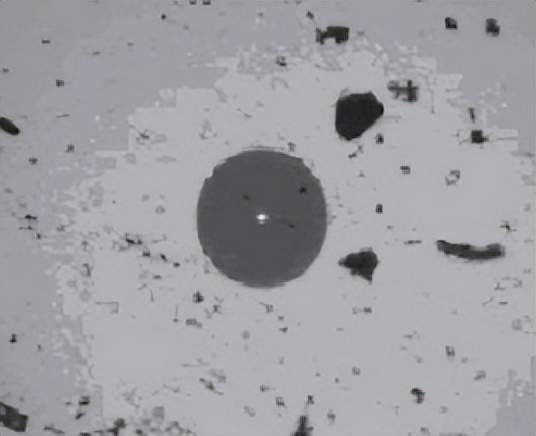

The "brittleness" of quartz optical fibers is manifested as follows: when the bending radius is less than the critical value, micro-cracks will occur in the fiber core (visible under a 20x microscope). When the crack extends to one-third of the diameter, the laser transmission loss increases from 0.2 dB/km to over 5 dB/km, directly resulting in insufficient welding energy. Meanwhile, scratches on the end face (depth > 1 μm) will cause laser scattering, leading to uneven energy distribution at the weld point (deviation can reach ±20%). The yield fluctuation of welding caused by micro-cracks in optical fibers is up to 5%, and this defect has a cumulative effect - continuous use will cause the cracks to continuously expand, and the fiber will completely fail in about 300 hours.

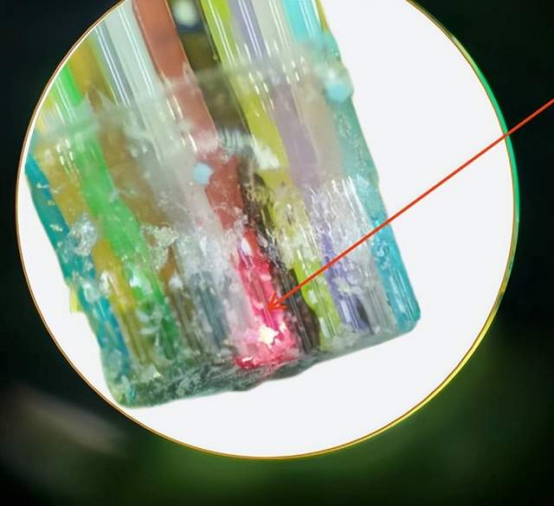

The "optical sensitivity" of optical fibers should also not be overlooked. once the end face (with a polishing accuracy of Ra ≤ 0.02 μm) is contaminated with dust particles larger than 0.5 μm, local high temperatures (> 1000 °C) will be generated when laser irradiation occurs, instantly eroding and forming pits. The reflected laser (with energy up to 30% of the incident light) will impact the laser resonant cavity in the reverse direction, reducing its lifespan by 50%. A dust particle with a diameter of 5 μm can completely damage the optical fiber end face after three laser pulses (100 W), and at the same time, the output power of the laser will decrease by 15%.

II. Basic Usage Specifications for Optical Fibers: From Physical Protection to Environmental Control

The basic usage norms for optical fibers aim to prevent mechanical damage and contamination, which is a prerequisite for ensuring the efficiency of laser transmission and should be adhered to throughout the entire process, including equipment installation, daily operation, and maintenance.

The core principle of mechanical protection is to strictly control bending and stress. Industry standards clearly stipulate that the minimum bending radius of optical fibers used for laser tin soldering should be ≥ 30 times the outer diameter of the fiber (for example, the minimum bending radius of a 600μm outer diameter fiber should be ≥ 18mm). When the continuous bending radius is < 20 times, the transmission loss will increase by 30% after 300 hours. In actual operation, "dead bends" (bending angle > 90°), twisting (torque > 0.5N·m), or hanging heavy objects (> 1kg) should be avoided. The optical fiber layout should adopt arc transition (curvature radius ≥ 50mm) and be fixed by special fixtures (interval ≤ 50cm). Dayan Intelligent Manufacturing will be equipped with optical fiber guide grooves when the equipment leaves the factory to ensure that the bending radius of the layout is ≥ 35mm, and support seats (load-bearing ≥ 5kg) will be set at the joints to avoid deformation of the flange due to force (a deviation in concentricity > 5μm will cause a loss increase of 2dB).

The key measures for end face protection are to prevent contamination and scratches. When the optical fiber is not in use, it must be immediately covered with a dust cap (made of polyethylene, hardness Shore A 60±5), and the dust cap needs to be treated with a cleanliness level of 100 (less than 35 particles ≥ 0.5 μm per cubic meter). Before installation, it should be operated on a 100-level super-clean workbench. Use an optical lens paper (non-shedding type) dipped in anhydrous ethanol (purity ≥ 99.9%) to wipe the end face in a "spiral trajectory" (avoid back-and-forth friction), and replace the lens paper each time it is wiped until no visible impurities are seen under a 20x microscope.

The basic requirement for environmental control is to reduce pollutant exposure. The cleanliness of the optical fiber operation area should reach 1000 grade (with no more than 3500 particles ≥ 0.5 μm per cubic meter), and the humidity should be controlled between 40% and 60% (excessive humidity can cause condensation, while too low humidity can cause dust). Operators should wear powder-free latex gloves (changed every hour) to avoid fingerprint contamination (fingerprint oil components can absorb laser and generate high temperatures). The welding station should be equipped with a local dust removal device (with an air velocity of 0.3 - 0.5 m/s) to keep the suspended particle concentration below 0.1 mg/m3.

III. Installation and Connection Specifications for Optical Fibers: Precision Control and Force Balance

The installation and connection of optical fibers are the key links that determine the efficiency of laser transmission. Their precision deviation and stress state directly affect the stability of welding quality, and precise alignment must be achieved through standardized operations.

The cleanliness control of the installation environment must meet strict standards. The optical fiber connection operation must be carried out on a 100-level super-clean bench (with a vertical laminar flow velocity of 0.45 m/s), with an anti-static rubber mat (with a surface resistance of 10? - 10? Ω) laid on the workbench. The operator must wear a grounded wrist strap (with an impedance of 1 MΩ) to prevent dust from being attracted by static electricity (static voltage > 100 V can attract particles larger than 0.1 μm). Before installation, the workbench surface should be wiped with isopropyl alcohol (with a purity of ≥ 99.7%), and non-operating areas should be covered with a lint-free cloth to reduce dust raised by air disturbance.

The key points of the connection operation are precise alignment and uniform force application. The concentricity of the optical fiber connector (common models are SMA905 and FC/PC) and the laser interface should be controlled within 3μm. When inserting, it should be smoothly advanced along the axial direction (with a thrust of 5-10N), and tilting should be avoided (an angle > 3° will cause poor end face contact). The torque of the threaded connection must be strictly controlled (0.8-1.0N·m for SMA905 connectors). If it is too loose (

Special protective measures should be designed specifically for different scenarios. For optical fibers longer than 5 meters, 2 to 3 support points (with a load-bearing capacity of ≥ 2kg) should be set in the middle to prevent sagging and bending due to self-weight (a deflection > 10mm will increase loss by 1dB). In robot integration scenarios, optical fibers should be equipped with drag chains (bending radius ≥ 50mm), and a 50mm redundant length should be reserved at the limit position of movement to prevent stretching (an elongation > 0.5% will cause the fiber core to break).

IV. Operating and Maintenance Specifications for Optical Fibers: From Power Monitoring to Lifespan Management

The operation and maintenance of optical fibers should combine real-time monitoring with regular maintenance to promptly identify potential problems and intervene, thus avoiding sudden failures that could cause production disruptions.

The key indicator for power monitoring is the stability of transmission efficiency. Under normal circumstances, the transmission efficiency of optical fibers (output power/input power) should be ≥ 90%, and the daily fluctuation should be < 2%. When the efficiency drops below 85% or the fluctuation exceeds 5%, the machine should be immediately shut down for inspection.

The core content of regular maintenance is end face cleaning and performance testing. It is recommended to inspect the end face with a 20x microscope for scratches and ablation before daily production, and conduct a thorough cleaning once a week (using an ultrasonic cleaner with a power of 30W for 30 seconds). Monthly transmission loss testing should be carried out (using an optical time-domain reflectometer OTDR), and the fiber should be replaced when the loss is greater than 1dB (continued use may cause laser overload). Maintenance data from a certain medical equipment manufacturer shows that the average lifespan of fibers that are cleaned weekly (1500 hours) is 87.5% longer than those cleaned irregularly (800 hours), and the welding energy stability (CPK value 1.8) is significantly higher than the latter (1.2).

The scientific approach to lifespan management is to establish a replacement cycle model. The service life of optical fibers is affected by usage frequency (daily welding frequency over 10,000 times will accelerate aging), power level (lifespan under 150W laser is 60% of that under 100W), and environmental cleanliness. Replacement plans should be formulated based on actual working conditions.

V. Conclusion

Optical fibers, as the "blood vessels" of laser tin soldering systems, their standardized use directly affects the welding quality, equipment lifespan and production costs. Dayan Intelligent Manufacturing will continue to be customer demand-oriented, through equipment innovation and service optimization, simplify the operation process of optical fibers, enhance their reliability, and provide stable and efficient laser welding solutions for precision electronic manufacturing. In actual production, enterprises need to incorporate optical fiber management into the SOP system, and combine the intelligent monitoring function of the equipment to build a "prevention first, precise maintenance" management model, so as to fully leverage the technical advantages of laser tin ball welding and maintain competitiveness in the field of micro-spacing and high-reliability welding.

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>