In-depth Analysis of the Laser Drilling Market in 2025

source:Old One

keywords:

Time:2025-09-17

Source: Old One 12th Sep 2025

Laser drilling technology, with its high precision, non-contact, and high efficiency features, holds a key position in many high-end manufacturing fields and can overcome the material and complex microstructure processing challenges that traditional processing methods find difficult to handle. Entering 2025, the global laser drilling market has shown many new dynamics. Some insiders even claim that the laser drilling market is the only segment in the laser industry that has achieved growth against the trend this year, with a significant increase in the sales of drilling equipment. Through the research of the 2025 mid-year reports of relevant listed laser enterprises, today we will discuss the current situation and future trends of the laser drilling market.

I. Market Size and Growth Trend

(1) The global market has been steadily rising.

The global impulse laser drilling market size was approximately 85.35 million US dollars in 2024 and is projected to soar to 214.43 million US dollars by 2034, with a compound annual growth rate (CAGR) of 9.65% during this period. This steady growth trend reflects the increasing importance of laser drilling technology in global manufacturing.

(2) Strong demand in the Chinese market

The market size of laser drilling equipment in China is expected to reach approximately 21 billion yuan in 2024 and is projected to grow to around 60 billion yuan by 2031, with an average annual growth rate of 15%. The vigorous development of industries such as 5G communication, new energy vehicles, and aerospace has become a strong driving force for the demand of laser drilling equipment in China. Take Han's CNC as an example. In the first half of 2025, the company seized the opportunity of the increasing demand and rising technical difficulty for high multi-layer boards in AI servers, and its new laser processing solutions for high-speed PCBs, substrate-like boards, and advanced packaging were highly favored by downstream customers, resulting in a significant increase in orders. The company achieved operating revenue of 2.382 billion yuan in the first half of the year, a substantial year-on-year growth of 52.26%, and a net profit attributable to shareholders of listed companies of 263 million yuan, a year-on-year increase of 83.82%. This fully demonstrates the huge potential and vitality of the Chinese market in the field of laser drilling.

II. New Trends in Technological Development

(1) Expansion of Applications of Ultrafast Laser Technology

Ultrafast laser technology (picosecond and femtosecond lasers) has significant advantages in processing brittle materials such as ceramics and glass, as well as in high-precision medical equipment, due to its "cold processing" feature (the heat-affected zone can be controlled to be less than 5 μm). Inno Laser, in response to the high-precision processing requirements of PCB/FPC in industries such as consumer electronics, semiconductors, and computing power, has successfully developed a series of lasers and laser equipment by adopting solid-state nanosecond and ultrafast laser technologies. Among them, the ultra-precision laser drilling equipment equipped with ultrafast lasers can stably process micro-holes with diameters of 30-70 μm, with a drilling efficiency of up to 10,000 holes per second. The first batch of samples has been highly recognized by customers, indicating that ultrafast laser technology is constantly achieving breakthroughs in practical applications.

(2) Advancement of Deep Ultraviolet (DUV) Laser Technology

Deep ultraviolet (DUV) laser technology can focus the light spot to less than 3 microns and performs well in the field of ultra-fine hole processing of semiconductor packaging substrates. As the semiconductor industry's requirements for the miniaturization (30-70μm) and high density of chip carrier substrate apertures become increasingly strict, the importance of deep ultraviolet laser technology is becoming more and more prominent. Relevant enterprises are also continuously increasing their R&D investment to promote the continuous upgrading of the technology.

(3) Intelligentization and Automation Upgrade

Hans Laser CNC has integrated artificial intelligence (AI) algorithms into its laser drilling equipment to automatically optimize process parameters such as laser power and frequency. By combining a visual positioning system with robot loading and unloading technology, it has created a fully automated processing flow. This not only boosts production efficiency but also ensures the stability of product quality, providing customers with more efficient and intelligent solutions.

(4) Implementation of Green Manufacturing Concepts

Many laser enterprises actively respond to the concept of green manufacturing by optimizing the optical path design and energy utilization rate to reduce the energy consumption of laser drilling equipment. This measure not only meets environmental protection requirements but also helps enterprises lower operating costs and enhance market competitiveness.

Yunteng Laser Double-Head Aluminum Sheet Drilling Equipment

III. Comprehensive Expansion of Application Fields

(1) Electronic Products and Semiconductor Packaging

With the rapid development of AI and 5G technologies, the miniaturization and high-density of chip carrier board apertures have become an urgent need. Laser drilling technology is widely used in the processing of micro-holes in circuit boards (such as PCBs, flexible circuit boards), connectors, semiconductor components, and packaging substrates (such as ABF, BT materials, cavity carrier boards). Han's CNC has been continuously making efforts in this field. In response to the processing requirements of high multi-layer HDI boards, it has developed a CO2 laser drilling machine with high power and real-time energy monitoring, which can achieve high-quality processing of large apertures and cross-layer blind holes. At the same time, its newly developed laser processing solution has broken through the bottleneck of large thermal effects of traditional CO2 lasers, meeting the high-quality requirements of micro-hole drilling and ultra-high precision profile forming processing, and has been recognized by downstream customers and received formal orders.

HANSO CNC HD650L2 Dual Light Source Dual Worktable CO2 Laser Drilling Machine

(2) Aerospace

The aerospace industry has strict requirements for high-precision drilling of components such as turbine blades, heat exchangers, and fuel systems, which need to be highly durable under high pressure and high temperature conditions. HuaGuang Technology has made significant breakthroughs in this field. Its six-axis laser micro-hole processing equipment for complex curved surfaces has overcome technical challenges such as multi-axis coordinated control and drilling of thermal barrier coatings with irregular shapes. It can complete the processing of micro-holes with diameters less than 0.5 millimeters in about 2 seconds, meeting the laser drilling, cutting, and welding needs of complex curved surface components such as combustion chambers and blades in aviation and aerospace engines. It has become a key equipment in the engine manufacturing industrial chain for aviation, aerospace, and marine industries.

(3) The Automotive Industry

In the automotive industry, laser drilling technology is applied to fuel injectors, exhaust pipes, brake components, etc., to enhance vehicle performance and safety. The rise of new energy vehicles has accelerated the use of lightweight materials, further promoting the development of laser drilling technology. For instance, the laser intelligent equipment business of Huaung Technology saw a significant year-on-year increase in orders from the new energy vehicle and shipbuilding industries in the first half of the year. Its application of laser drilling technology in the automotive industry has been widely recognized by the market.

(4) Medical Devices

Medical devices have extremely high requirements for precision and reliability. The advantages of laser "cold processing" are in line with the demands of this field. As a leading domestic solid-state laser manufacturer, Innolase's business covers the biomedical field. Its related laser technologies and equipment provide strong support for the precise processing of medical devices, promoting the development of the medical device industry.

(5) Ceramic Materials

Laser drilling technology can create smooth and non-fragile small holes on ceramic materials such as tiles, insulators, filters, and sensors. With the growth of market demand for high-quality and undamaged ceramic processing, related enterprises are constantly optimizing laser drilling processes to improve processing quality and efficiency to meet market needs.

IV. Competitive Landscape and Focus

(1) Competitive Advantages of International Enterprises

Internationally, companies such as Coherent, Rofin, EDAC, IPG, and SPI hold significant positions in the laser drilling market. With advanced technologies, rich experience, and extensive market coverage, they enjoy a high share in the global high-end market. For instance, Coherent leads in ultrafast laser technology, and its products are widely used in high-end fields such as semiconductors and medical applications.

(2) Domestic Enterprise Development Momentum

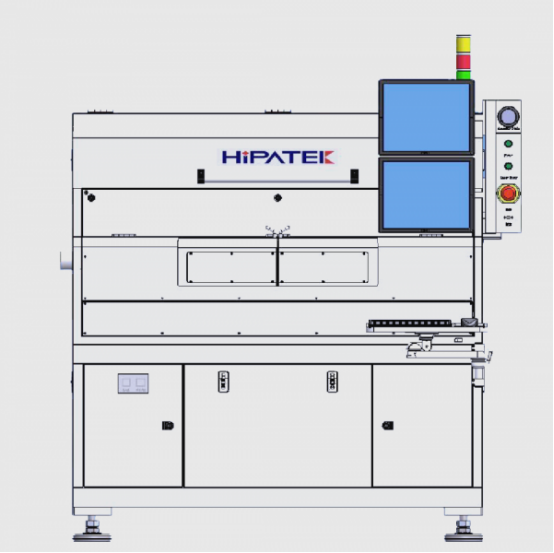

Domestic enterprises such as Han's Laser, HGLASER, Inno Laser, and EXCST are developing rapidly and continuously narrowing the gap with international companies. Han's CNC, a subsidiary of Han's Laser, has a wide range of products in the PCB-specific equipment field. Its drilling equipment achieved an operating income of 1.692 billion yuan in the first half of 2025, a year-on-year increase of 72%. The company's laser drilling equipment product matrix is rich, and it continuously upgrades product performance in the HDI product field to meet market demands. HGLASER has made multiple breakthroughs in laser drilling technology in the aerospace, automotive, and other fields. Its six-axis laser micro-hole processing equipment for complex curved surfaces demonstrates strong technical strength. Inno Laser maintains a leading position in the laser business and custom-develops a series of lasers for various applications such as PCB, effectively supporting the development of new businesses. EXCST focuses on the research and development, production, and sales of automated high-precision laser application equipment. Its products such as the PCB laser blind hole drilling machine have certain competitiveness in the market. Even the start-up laser micro-processing equipment manufacturer, Dongguan HiPATEK Technology Co., Ltd., has achieved a doubling of its output value this year by serving major customers such as Shenzhen Circuits with equipment like the UV high-speed drilling machine HP-D-UV1000.

HGLASER Six-Axis Laser Micro-Hole Machining Equipment for Complex Curved Surfaces

HiPATEK Technology Co., Ltd. UV High-Speed Drilling Machine HP-D-UV1000

(3) Analysis of Competitive Focus

The current market competition focuses on technological innovation, cost control and the ability to provide customized solutions. In terms of technological innovation, enterprises continuously invest in research and development to enhance the precision and efficiency of laser drilling and explore new application areas. For instance, Inno Laser has been consistently developing leading products around the directions of "short pulse or continuous pulse, short wavelength, and high power". Regarding cost control, due to the high initial investment cost of laser drilling equipment, enterprises reduce costs by optimizing production processes and increasing the localization rate of components. The ability to provide customized solutions is also crucial. Han's CNC has been deeply cooperating with leading PCB manufacturers downstream, providing personalized customized solutions for different demands, and achieving a high level of domestic substitution of laser drilling equipment.

V. Outlook on Future Trends

(1) Acceleration of Technological Convergence and Innovation

In the future, the application of ultrafast lasers will become more widespread, and laser drilling equipment will be deeply integrated with artificial intelligence, machine vision, and industrial Internet of Things (IIoT) technologies. Through intelligent monitoring, predictive maintenance, and process adaptive optimization, the production process will be made intelligent and efficient. For instance, the equipment can collect real-time operation data through sensors, analyze it using AI algorithms, predict faults in advance, and optimize process parameters, thereby enhancing production efficiency and product quality.

(2) Continuous Expansion of Application Fields

In emerging fields such as renewable energy (like solar panels), medical devices (such as implantable devices), and consumer electronics (for instance, wearable devices), laser drilling technology is set to encounter new growth opportunities. As technologies in these areas continue to advance and market demands increase, higher requirements are placed on the precision and efficiency of laser drilling, driving enterprises to constantly innovate and expand their applications.

(3) Development of Equipment Integration and Modularization

Laser processing equipment will evolve from single-function to integrated (combining multiple functions such as drilling, cutting, marking, and inspection) and modular designs, providing customers with full-process solutions. This not only enhances the utilization efficiency of the equipment but also reduces the procurement and maintenance costs for customers. For instance, an integrated laser processing machine can complete various processing tasks on the same worktable, reducing the floor space occupied by the equipment and the turnover time between processes.

(4) Green and sustainable development becomes mainstream

Energy conservation and environmental protection will become important considerations in equipment research and development. Enterprises will promote green manufacturing by improving energy utilization efficiency and reducing waste emissions. For instance, they will adopt new optical materials and optimize the optical path design to enhance the utilization rate of laser energy and reduce equipment energy consumption; they will also develop environmentally friendly laser processing auxiliary materials to minimize environmental pollution.

In conclusion, the laser drilling market in 2025 is promising but full of challenges. The continuous technological advancements provide a strong impetus for market development, while the vigorous demand from downstream industries lays a solid foundation for market growth. For investors and market participants, keeping up with the latest technological trends, focusing on the demands of popular downstream application areas, and offering solutions that reduce the total cost of ownership (TCO) are the keys to seizing market opportunities and standing out in the fierce competition.

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>