China 3D printing tech sets world record making fatigue-resistant Ti alloy

source:China News Service

keywords:

Time:2025-09-05

Source: China News Service 1st September 2025

On August 29th, the Institute of metal Research of the Chinese Academy of Sciences disclosed that its research team has recently developed a new post-processing technology for 3D printing (also known as additive manufacturing), creating a titanium alloy material hailed as "all-round" fatigue-resistant, which has set a new world record for metal materials' fatigue resistance.

This important research, which has removed a major obstacle for the application of 3D printing technology in high-precision and high-end fields, was completed by the research team led by Professors Zhang Zhefeng and Zhang Zhenjun from the Institute of metal Research, Chinese Academy of Sciences. The related research paper was recently published in the international academic journal Science Advances.

The research team explained that "all-round" fatigue resistance refers to the unprecedented fatigue resistance demonstrated under various stress ratio conditions, that is, the ability to withstand repeated forces without damage.

They introduced that 3D printing can easily produce metal parts with complex structures and light weight, which is highly attractive for the new generation of high-end equipment such as aircraft and spacecraft that pursue weight reduction and integration. However, for a long time, there has been a "hard defect" in the metal parts printed by 3D printing - poor fatigue performance, that is, they are prone to cracks or even fractures after repeated stress, which seriously restricts their key applications.

In early 2024, a research team invented a new process called Net-AM Preparation (NAMP), which can precisely control the internal structure and defects of materials. The Ti-6Al-4V (one of the most commonly used titanium alloys) prepared by this new process can simultaneously eliminate micro-pores and coarse structures - both of which are the main culprits causing fatigue. Under cyclic "tensile-tensile" stress conditions, this new material broke the world record for "specific fatigue strength" (strength divided by density, a key indicator for evaluating the performance of lightweight materials), proving that 3D printed materials can also have top-notch fatigue resistance.

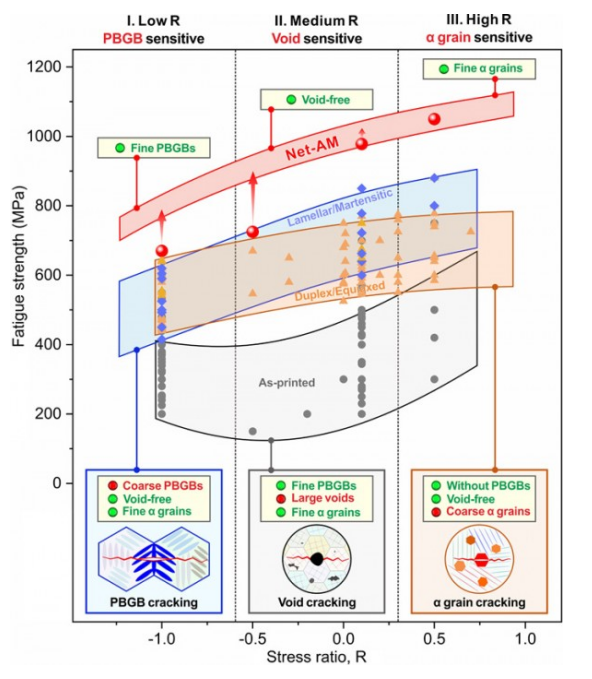

However, in reality, the force conditions of metal parts such as aircraft engine blades and landing gears are very complex. They not only experience "tension-tension" but also "tension-compression" and other situations, meaning that the stress ratio is changing. Different stress ratios can trigger different damage mechanisms within the material. Moreover, the microstructure of traditional titanium alloys is often "one-sided": they only perform well under certain specific stress ratios, but may perform poorly under another stress ratio. This makes it very difficult to create a material that can handle all working conditions.

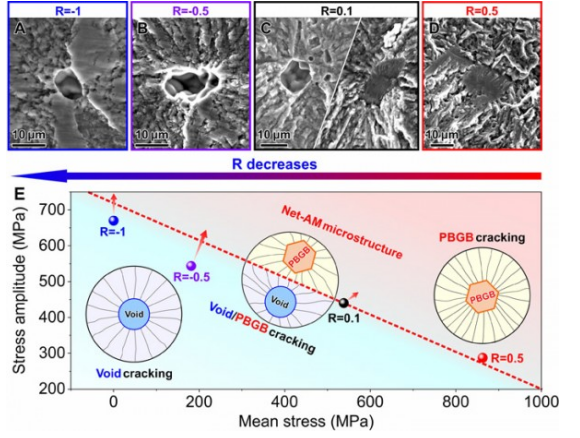

In this study, in the face of this more complex challenge, the research team analyzed and revealed several weak links in titanium alloys that are prone to fatigue cracking, as well as under which loading modes they would "manifest". based on this, the research team utilized the NAMP process to manufacture nearly pore-free 3D printed structures, which can simultaneously optimize all these weak links. This 3D printed titanium alloy possesses the characteristic of maintaining high fatigue strength under all stress ratios.

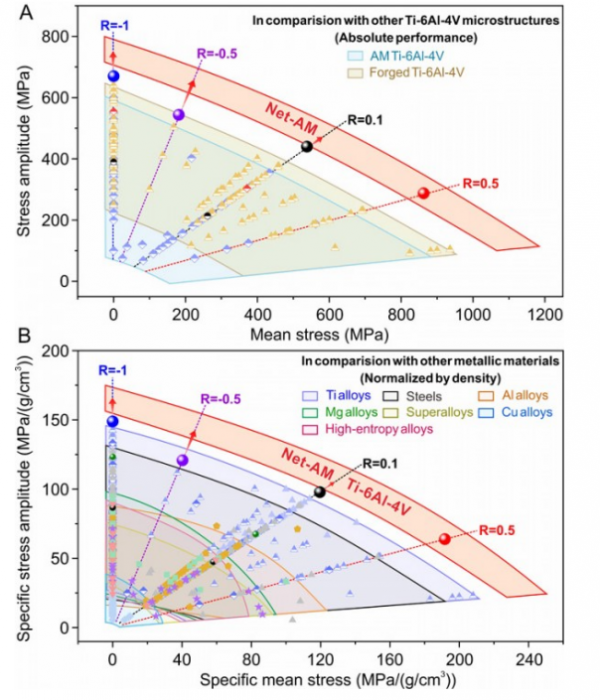

Experimental data show that in fatigue tests with different stress ratios, the "all-round" fatigue-resistant titanium alloy material has a "fatigue strength ratio" that is superior to all metal materials in all aspects.

The fatigue strength of Ti-6Al-4V alloys with different microstructure types under different stress ratio conditions and the corresponding fatigue crack initiation mechanisms.

The typical fatigue fracture surfaces of Ti-6Al-4V alloy under different stress ratios organized by Net-AM and the corresponding fatigue crack initiation mechanisms.

The fatigue strength distribution of Net-AM structured Ti-6Al-4V alloy under different stress ratios compared with other Ti-6Al-4V alloys and common metallic structural materials.

9th Secret Light Awards Launch: Million-Yuan Fund + National Award Recommendation

9th Secret Light Awards Launch: Million-Yuan Fund + National Award Recommendation Top Enterprises Gather: 1st Laser & Additive Manufacturing Innovation Conference Wraps Up

Top Enterprises Gather: 1st Laser & Additive Manufacturing Innovation Conference Wraps Up 2025 ams OSRAM Explorer Conference: "China Engine" Drives Future Innovation

2025 ams OSRAM Explorer Conference: "China Engine" Drives Future Innovation Tsinghua's Sun Hongbo, SLA Review Expert, Becomes CAS Academician

Tsinghua's Sun Hongbo, SLA Review Expert, Becomes CAS Academician 4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms?

4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms?

Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer

Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources

more>>

Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources

more>>